The Finishing Touch for Your Vessel

Yacht sign installation is the art of mounting custom lettering, logos, or name boards onto your vessel, creating a visual identity that reflects your style and ensures proper identification.

Key aspects of yacht sign installation:

- Professional installation typically takes 1-3 days depending on sign complexity

- Precise drilling and sealing prevents water ingress into the hull

- Marine-grade materials like 316L stainless steel ensure long-term durability

- CNC-cut templates guarantee perfect alignment and spacing

- Illuminated signs require electrical connections and specialized expertise

- Surface protection during installation prevents damage to paint and teak

As one yacht owner noted, “Enhancing your yacht name with illuminated yacht lettering is the finishing touch you both deserve.”

The process involves careful preparation, precise alignment, and expert craftsmanship. Proper installation is crucial for both aesthetics and long-term performance in the harsh marine environment, whether for stainless steel letters or custom LED name boards.

Professional installation offers peace of mind through proper sealing, electrical connections, and surface protection, while some smaller non-illuminated signs can be owner-installed with the right tools and techniques.

I’m Cole Reilly. With nearly two decades of experience in yacht sign installation and over 10,000 completed projects, I’ve seen how the right signage transforms a vessel. This guide covers everything from planning to maintenance.

Yacht sign installation vocab explained:

Understanding Your Yacht Sign: Materials and Illumination

Before the yacht sign installation process, understand what makes an exceptional yacht sign. It must be stunning while withstanding the harsh marine environment.

The secret is choosing the right materials and illumination. Cutting corners on materials leads to poor aging and costly replacements.

Types of Yacht Signs

We offer several distinct sign styles to match your vision. 3D Lettering for Boats creates a sophisticated dimensional look where individual letters stand proudly off your hull, casting subtle shadows.

Name boards offer a more traditional approach, providing a classic foundation for your yacht’s identity with engraved lettering or applied graphics.

Custom logos take personalization to the next level, whether it’s a family crest, company emblem, or a meaningful symbol. These can stand alone or integrate with your name display.

Illuminated Yacht Signs transform your vessel into a guide of style after sunset, with your yacht’s name glowing softly against the water.

Non-illuminated dimensional signs rely on premium materials and expert craftsmanship to create presence and depth without electrical components.

Marine-Grade Materials: Built to Last

The marine environment is brutal, with constant saltwater spray and UV exposure. To prevent costly mistakes, we exclusively use marine-grade materials designed for these harsh conditions.

Stainless Steel Yacht Signs represent our gold standard. We use 316L stainless steel, the same grade used in surgical instruments. The 316L grade contains molybdenum for superior corrosion resistance against saltwater, unlike standard stainless steel.

You can choose from several finishes: mirror polished for maximum shine, satin brushed for understated elegance, or titanium gold for a touch of luxury.

Marine-grade acrylic offers incredible versatility. It’s lightweight, UV stable, and available in virtually any color, creating an even, beautiful glow when backlit.

Naval brass brings warmth and tradition, formulated to resist saltwater corrosion while developing a beautiful patina over time.

Aluminum is an excellent lightweight option that can be powder-coated in any color, offering great corrosion resistance at an accessible price point.

Illumination Options for Brilliance at Sea

Illumination transforms your yacht sign from good to extraordinary. Our LED Yacht Signs combine traditional craftsmanship with cutting-edge LED technology.

Backlit illumination creates a coveted halo effect, with LEDs casting a soft glow that outlines each letter.

Face-lit signs provide maximum visibility by shining light directly through translucent letter faces, ensuring your yacht’s name is clearly visible from a distance.

Edge-lit options offer subtle elegance, with LEDs along the edges of clear acrylic letters creating a gentle glow that highlights engraved details.

RGB color-changing capabilities let you match your mood or celebrate special occasions, from neat white to festive holiday displays.

The benefits include better nighttime visibility, increased safety, and a striking presence. Modern LEDs are energy-efficient, drawing minimal power and lasting 2-8 years depending on usage.

From Concept to Creation: The Design and Manufacturing Process

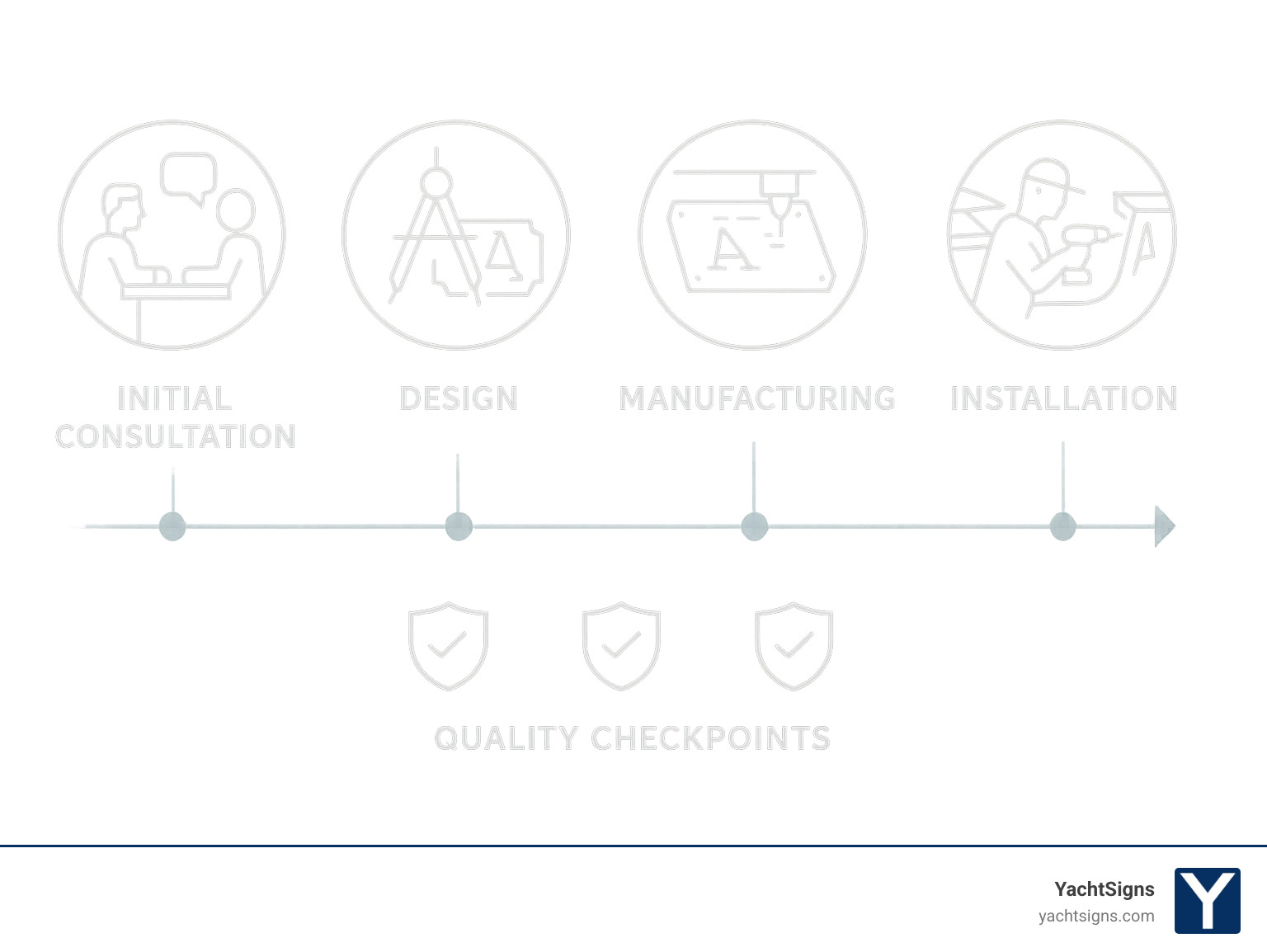

Creating your custom yacht sign is a collaborative process. We blend artistic design with precision manufacturing to transform your unique vision into a handcrafted masterpiece, never taking a cookie-cutter approach.

From idea to final yacht sign installation, our team collaborates with you, combining artisan traditions with modern technology to meet the exacting standards of luxury yachts.

The Design Phase: Bringing Your Vision to Life

Our designers and specialists consult with you to understand your vision, whether it’s a clear concept or just the beginning of an idea.

The initial consultation covers your yacht’s personality, your style, and practical considerations like viewing angles. We take our time to get it right.

On-site measurements are crucial for a flawless result. Our specialists visit your yacht to document every detail of the mounting area, including curves, angles, and existing hardware.

Font selection is part of the fun. We guide you through an extensive library of typefaces, from traditional to modern. You might find inspiration from Google Fonts, or we can develop completely custom lettering.

Digital renderings bring the design to life. Using your yacht’s measurements, we create photorealistic mock-ups showing exactly how the sign will look, accounting for light and perspective.

The approval process ensures the final product is exactly what you envisioned, with no surprises.

Precision Manufacturing: Where Craftsmanship Meets Technology

Once you approve the design, our skilled artisans take over. Every sign is manufactured in the USA, combining state-of-the-art technology with hand-finishing that machines cannot replicate.

CNC cutting handles precision work, cutting materials like acrylic and aluminum with microscopic tolerances to perfectly match the approved design.

For intricate details, laser cutting creates incredibly precise cuts without mechanical stress, which is vital for delicate elements.

Water-jet cutting is used for thicker metals and complex shapes, cutting through materials with a high-pressure stream of water without introducing heat distortion.

The real artistry is in the hand-finishing. Our craftspeople carefully deburr, sand, and polish every surface to achieve the perfect finish, whether mirror-bright or satin-brushed.

Painting and specialized finishes add the final touches. We use marine-grade coatings and proven techniques to ensure your sign is both stunning and durable.

The production timeline is typically one to six weeks, depending on complexity. We can often expedite production and will provide a realistic timeline upfront, keeping you updated throughout the process.

The Complete Guide to Yacht Sign Installation

Yacht sign installation is where your custom sign becomes a permanent part of your vessel’s identity. The process is both an art and a science, requiring precision, experience, and respect for your yacht’s integrity. Proper installation is critical to protect your investment, ensuring both stunning aesthetics and long-term structural integrity.

Professional Yacht Sign Installation: Ensuring a Flawless Finish

For yacht sign installation, especially illuminated signs, professional expertise is essential. Our technicians have decades of combined experience on vessels from 10 to 110 meters across the globe. The peace of mind that comes with professional installation is invaluable.

Site preparation starts before we arrive. We coordinate marina access, arrange for equipment like ladders or scaffolding, and ensure access to mains electricity for testing.

Surface protection is a priority. We carefully cover painted surfaces and teak decking with protective materials like blue foam to prevent any damage.

Our CNC-cut templates ensure precision. For transom installations, we align to the centerline. For side installations, we fine-tune the alignment visually from the dock, as yachts rarely sit perfectly level in the water.

Drilling and sealing is a normal part of installing illuminated signs. We create minimal, carefully placed holes for mounting and wiring, mapped with templates to avoid obstructions. Each hole is sealed with marine-grade sealant to prevent water ingress.

For any threads and fixings that contact dissimilar metals, we apply Tef Gel to reduce electrolysis risk—a small detail that prevents big problems.

Water ingress prevention is absolutely critical. Our technicians ensure every penetration is properly sealed and all wiring is routed to prevent moisture issues.

Electrical connections for illuminated signs require delicate handling. We secure all wiring to prevent tugging or kinking, and all connections are made safe and weather-sealed. When possible, we prefer interior access to gather wires and tighten fixings.

The installation timeline is typically one day for a single sign, though larger projects may extend to three days. We work tidily and clean up thoroughly upon completion.

We travel worldwide for installations, partnering with trusted professionals in Europe, Asia, North America, the Middle East, and Australia and handling all logistics for a stress-free process.

Owner-Assisted Yacht Sign Installation: What You Need to Know

While professional yacht sign installation is highly recommended, some smaller, non-illuminated signs (like vinyl decals) can be owner-installed. This is generally suitable for simpler applications on boats under 40 feet.

If you’re considering the DIY route, you’ll need basic tools: a tape measure, painter’s tape, a squeegee, and appropriate cleaning solutions. For adhesive signs, ensure you have a suitable marine-grade adhesive.

Alignment techniques are crucial. Use painter’s tape for guidelines and measure carefully. A paper template from the manufacturer is incredibly helpful.

The application process varies. For vinyl, clean the surface, position the decal, and apply slowly with a squeegee. For adhesive-backed letters, apply to a clean, dry surface, following your template.

However, potential risks are real: improper alignment looks unprofessional, poor adhesion can lead to detachment, and improper sealing during any drilling can cause costly and dangerous water ingress. For these reasons, we always recommend professional installation for anything beyond simple vinyl decals.

Longevity, Maintenance, and Cost Considerations

A professional yacht sign installation is an investment in your vessel’s identity. Proper care ensures your custom sign provides years of stunning performance. To protect your investment and keep your sign gleaming, let’s discuss durability, maintenance, and cost.

Durability and Maintenance: Protecting Your Investment

Our yacht signs are built to withstand the marine environment. The sign lifespan depends on materials and maintenance, but we design every piece for long-term performance.

Our LEDs last 2-8 years depending on usage. We back our lighting components with a 3-year warranty for your confidence.

The key to a showroom appearance is a simple cleaning routine. Regularly rinse with fresh warm water and use a microfiber cloth to prevent salt buildup that can dull the finish.

For stubborn stains, use warm water with mild detergent. Crucially, avoid abrasive cleaners. They can create hairline scratches on mirror finishes, leading to expensive refinishing.

Preventing electrolysis is vital. We apply Tef Gel during installation. You should also immediately clean away any metal debris or drilling particles after work is done near the sign to prevent stains.

Our team at Yacht Signs Fort Lauderdale is always available to provide maintenance guidance and support for our Florida-based clients.

Understanding the Cost of Custom Yacht Signs

Pricing for our custom yacht signs is unique to each project. We consider several key factors that influence the cost.

Sign size plays a fundamental role, as larger signs require more materials and complex manufacturing.

Your material choice significantly impacts the cost. Marine-grade acrylic offers great value, while 316L stainless steel represents a higher investment.

Illumination type adds another dimension. Non-illuminated signs have one price point, while backlit LED systems or RGB color-changing capabilities require more complex components and manufacturing.

Finish complexity can transform appearance and cost. A satin-brushed finish requires different labor than a mirror-polished one, and custom finishes involve additional expertise.

The installation scope also factors in. Dock-side access differs from installations requiring scaffolding or international travel.

As your trusted Yacht Sign Supplier, we provide detailed, custom quotes to make your vision a reality within your budget.

Frequently Asked Questions about Yacht Sign Installation

After thousands of installations, we’ve heard every question imaginable. Here are answers to the most common ones about yacht sign installation.

Do I need to drill holes into my yacht for an illuminated sign?

Yes, drilling holes into your yacht’s hull is a necessary and standard practice for installing illuminated signs. These holes are for mounting studs and wiring pass-throughs.

We keep holes to a minimum, using precision CNC-cut templates to avoid internal obstructions. Every hole is then thoroughly sealed with marine-grade sealants to prevent any water ingress.

Our team has perfected this process, ensuring the hull’s integrity is never compromised. Professional sealing techniques are critical for a quality installation.

Can a sign be installed while the yacht is in the water?

Absolutely. In-water installation is very common practice, and our teams are equipped to handle it anywhere, from Fort Lauderdale to Monaco.

However, dry land installation is often preferred when possible. It allows for scaffolding and easier access, which is helpful for larger or more complex projects.

Don’t worry if dry-docking isn’t possible. Our marine installation specialists come prepared with proper safety equipment and will coordinate all access requirements with you and your marina.

What happens if I’m renaming my yacht?

Renaming a yacht requires careful preparation to ensure a seamless transition for your new sign.

Crucially, old sign removal and surface preparation must be completed before our technicians arrive for the new yacht sign installation. The surface must be perfect.

The process involves removing the old name, filling any old mounting holes, and fairing the surface to create a smooth base.

Finally, the area typically needs repainting to match the surrounding hull finish. This ensures your new sign sits on a flawless surface.

We can provide guidance and recommend trusted marine painters. A properly prepared surface makes all the difference for the final result.

Conclusion: Lift Your Yacht’s Identity with a Perfectly Installed Sign

Your yacht deserves an identity that turns heads. A professional yacht sign installation is the final stroke that transforms your vessel, creating a lasting impression that reflects your personal style.

This guide covered the journey from selecting marine-grade materials and illumination options to the final installation. We’ve shown how our design process turns your vision into reality and how our precision manufacturing combines craftsmanship with technology, all proudly made in the USA.

Most importantly, we’ve emphasized why professional yacht sign installation is critical. The details—from precise drilling and sealing to expert electrical work—ensure a sign that performs flawlessly for years.

Proper maintenance is your key to protecting this investment. A simple routine of fresh water rinsing and gentle cleaning will keep your sign gleaming, while our 3-year warranty provides peace of mind.

With nearly two decades of experience and over 10,000 projects completed worldwide, we offer a comprehensive, in-house service from design to installation and provide ongoing support.

Your yacht’s identity is waiting to shine. The combination of quality materials, professional installation, and proper maintenance creates signage engineered for the elements.

Ready to see what’s possible for your vessel? View our portfolio of exceptional yacht signs and find how the perfect sign can transform your yacht’s presence on the water.