The Importance of Lasting Impressions

UV resistant signs are specially designed to withstand ultraviolet radiation from sunlight, preventing the fading, cracking, and deterioration that diminishes a luxury vessel’s elegance. Nothing compromises a yacht’s appearance faster than worn-out signage.

Key Features:

- Materials: Marine-grade stainless steel (316L), acrylics, polycarbonate, and UV-stabilized plastics

- Protection: UV inhibitors, protective coatings, and weatherable films

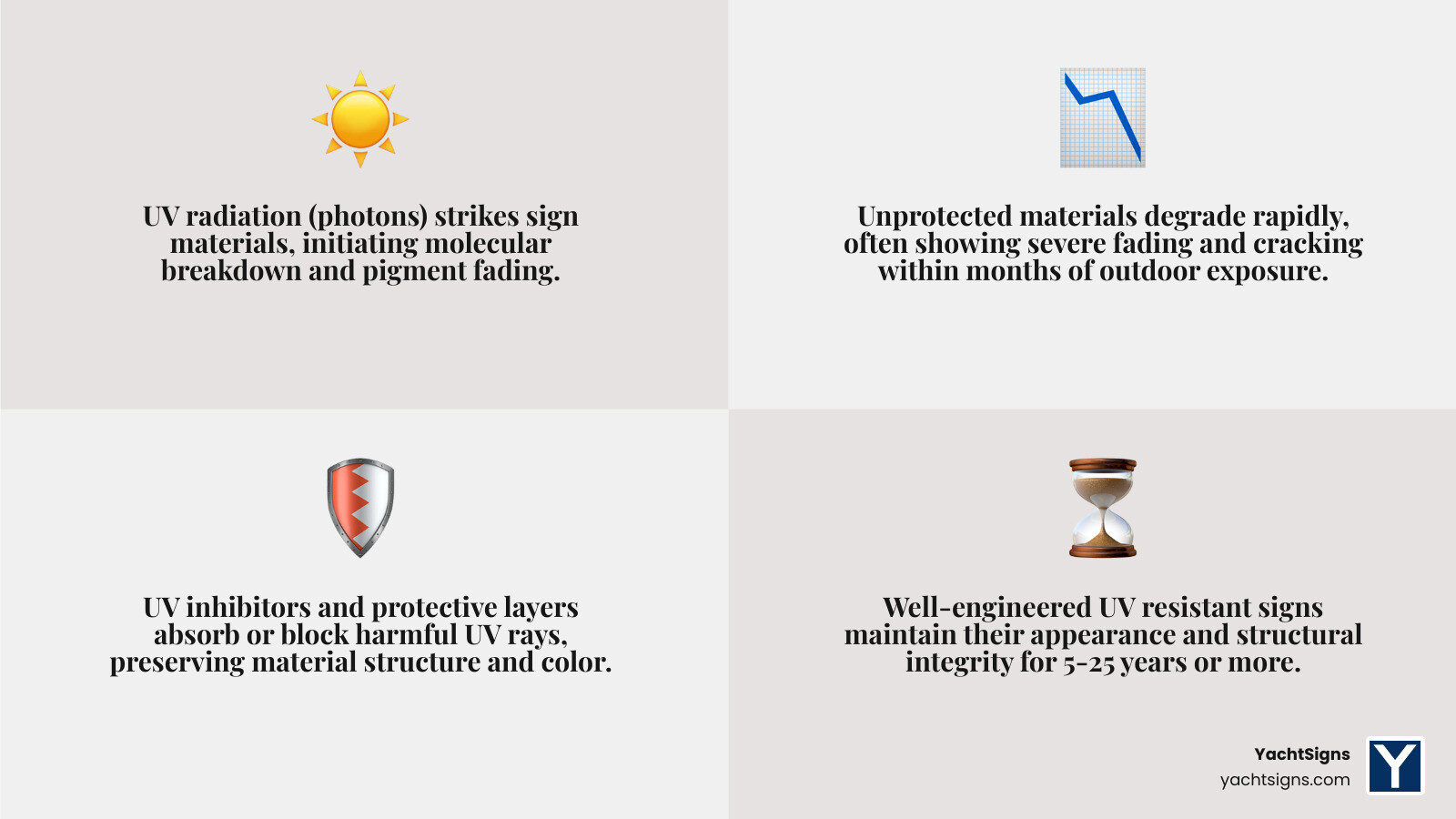

- Lifespan: 5-25 years depending on material and environmental conditions

- Applications: Yacht lettering, outdoor business signs, marine environments, and architectural signage

Your yacht is a significant investment reflecting your personal style. First impressions matter, especially in the marine world where attention to detail is paramount. Unprotected materials can degrade in less than a year outdoors, while properly engineered UV resistant signs maintain their appearance and integrity for decades. This is about protecting your brand and ensuring your vessel commands respect.

I’m Cole Reilly, and after nearly two decades at Yacht Lettering and over 10,000 custom projects, I’ve seen how the right UV resistant signs transform a vessel’s appearance while enduring the harshest marine conditions. Luxury yacht owners demand perfection, and our signs deliver it.

UV resistant signs terms at a glance:

The Science of Durability: Understanding UV Resistance

Every time sunlight hits your yacht’s signage, an invisible battle occurs. UV radiation carries powerful photons that break down the chemical bonds in sign materials, causing molecular breakdown. Pigments fade, and the material’s structure degrades, leading to a chalky, brittle appearance. This isn’t just cosmetic damage; it’s structural failure. A standard sign can show serious degradation in just a few months in high-UV environments like the open ocean.

UV resistance is the ability of a material to withstand the degradation that can be caused by exposure to ultraviolet light. For UV resistant signs on luxury vessels, this property is critical for maintaining a pristine appearance.

How UV Protection is Achieved

We win this molecular battle with ingenious science:

- UV Inhibitors: These chemical compounds are mixed into the material to absorb harmful UV radiation and convert it into harmless heat before it can cause damage.

- UV Stabilizers: These additives neutralize the damaging free radicals created by UV exposure, which can double the resistance of unprotected plastic.

- Protective Coatings & Lamination Films: A true outdoor weatherable film creates a physical barrier that can protect signage for 5 to 25 years. This surface protection is key for longevity in harsh marine conditions, far outperforming materials with only internal (bulk) additives.

- UV-Cured Inks: These specialized inks cure instantly under UV light, forming a durable, fade-resistant surface that also resists humidity and temperature changes.

This combination of advanced materials, inks, and protective finishes ensures your yacht’s signage maintains its stunning appearance year after year, reflecting the quality that defines your vessel.

Selecting the Ideal Material for Your UV Resistant Signs

Choosing the right material for your UV resistant signs starts with one question: Where will this sign live? The marine environment is unforgiving, with salt spray, intense UV radiation, and moisture that can destroy ordinary signage. Material selection is about engineering a solution that balances aesthetics, environmental factors, and budget for long-term value.

Here’s how the most popular UV resistant sign materials compare in real-world marine applications:

| Material Type | Durability & UV Resistance | Cost Range | Best Applications |

|---|---|---|---|

| Acrylic (Plexiglass) | Excellent – less than 3% degradation over 10 years | Moderate | Illuminated lettering, clear panels, modern aesthetics |

| 316L Marine Stainless Steel | Outstanding – naturally UV immune, 8+ year LED lifespan | Premium | Yacht lettering, harsh saltwater environments |

| PVC Plastic | Good – 5+ years with UV inks and proper care | Budget-friendly | Commercial signage, temporary applications |

| Aluminum Composite (ACM) | Excellent – twice as rigid as aluminum, 50% lighter | Moderate-High | Large format signs, architectural applications |

| Polycarbonate | Very Good – extremely impact resistant | Moderate | High-traffic areas, safety applications |

High-Performance Plastics and Acrylics

For a perfect combination of clarity, vibrant color, and modern sophistication, high-performance plastics are an ideal choice for UV resistant signs.

- Acrylic (Plexiglass): Remarkable for marine applications, showing less than 3% degradation over ten years. Its inherent UV resistance and optical clarity make it perfect for illuminated yacht lettering.

- Polycarbonate: Offers similar clarity with 30 times the impact resistance of acrylic. It’s ideal for high-traffic areas, though some grades may require extra UV-protective treatments to prevent yellowing over time.

- PVC Plastic: An excellent value, our acid-free, closed-cell PVC is durable and eco-friendly. We print directly onto the surface with UV-cured inks for a long-lasting finish that performs well for 5+ years.

- High-Density Polyethylene (HDPE): With added UV inhibitors, HDPE offers exceptional chemical resistance and durability, making it perfect for utility signage.

Resilient Metals and Composites

For ultimate longevity and a premium finish, nothing matches quality metals and composites.

- 316L Marine-Grade Stainless Steel: The gold standard for marine signage. The 316L grade contains molybdenum for superior corrosion resistance in saltwater and is naturally UV-immune. Our illuminated stainless steel lettering can last for decades, with LED systems designed for an 8-year lifespan. More info about our lighting solutions

- Aluminum: A lightweight, rust-resistant option. Its UV resistance comes from professional powder coatings or two-part marine paints.

- Aluminum Composite Material (ACM): Twice as rigid as solid aluminum but 50% lighter, ACM is perfect for large-format signs where weight and stability are key.

Protective Finishes and Printing Methods for UV resistant signs

Even the best materials need the right finish. These final layers separate good UV resistant signs from exceptional ones.

- UV-Cured Inks: We use inks with photosensitive resins that cure instantly under UV light, creating a tough, fade-resistant surface integral to the sign.

- Two-Part Marine Paints: The same professional-grade paints used on yacht hulls, offering unparalleled durability, gloss retention, and color integrity.

- Protective Clear Coats & Lamination: This sacrificial barrier takes the punishment from UV rays and moisture, extending a sign’s fade-free performance to 3-5 years in harsh conditions.

This integrated approach ensures superior color retention and abrasion resistance, resulting in signs that exceed the most demanding expectations.

Key Factors Influencing the Longevity of Your Signage

While premium materials are crucial, the lifespan of your UV resistant signs is also influenced by external factors. Understanding these elements helps us design for maximum durability.

Environmental Exposure and Location

A sign’s environment is a primary determinant of its longevity.

- Sunlight Intensity and UV Index: Locations with high UV indexes (e.g., equatorial regions) exert more stress on materials, accelerating degradation.

- Climate Conditions: Extreme heat and cold cause materials to expand and contract, leading to stress and cracking. High humidity can also encourage mildew.

- Coastal Environments and Salt Spray: Marine environments are notoriously harsh. Salt spray accelerates corrosion, which is why we use marine-grade materials and specialized coatings.

- Industrial Pollutants: Airborne pollutants in some areas can chemically attack sign surfaces, causing them to fade faster.

Proper Maintenance for Lasting Brilliance

Even the most robust UV resistant signs benefit from proper maintenance to extend their lifespan.

- Cleaning Procedures: Routinely clean with a soft cloth and mild detergent. Avoid abrasive chemicals or scrub brushes that can scratch surfaces or strip protective coatings. Hosing off saltwater residue is a simple, effective step.

- Inspection Schedule: Periodically inspect signs for wear, such as scratches or dirt build-up. Early detection prevents minor issues from escalating.

- Avoiding Harsh Chemicals: Never use solvents, strong acids, or alkaline cleaners. Always use cleaners designed for your sign’s specific material.

Diligent maintenance preserves your sign’s aesthetic appeal and structural integrity, ensuring its UV resistant properties remain effective.

The Long-Term Value: Benefits and Applications

Investing in high-quality UV resistant signs is a strategic decision that offers significant long-term value. Choosing quality materials and expert craftsmanship protects your message and your budget for years to come.

Tangible Benefits of Investing in Quality

- Cost-Effectiveness: While the initial investment may be higher, a sign that lasts 5-10 years is far more economical than one needing replacement every year or two. This means fewer replacement costs and less hassle.

- Maintained Visibility & Safety: UV resistant materials prevent fading, ensuring that vibrant colors and critical information remain clear. This is crucial for brand integrity and for safety signs where legibility can be life-saving.

- Brand Integrity: For yacht owners, crisp, vibrant UV resistant signs reinforce a professional image and convey attention to detail, unlike faded signs that suggest neglect.

Common Applications for UV resistant signs

The durability of UV resistant signs makes them essential for any outdoor application. While our specialty is marine and yacht lettering, where we combat the harshest combination of UV, salt, and moisture, the principles apply broadly to:

- Business storefronts and architectural signage

- Wayfinding systems for parks and campuses

- Industrial safety and construction site signs

- Real estate and outdoor event signage

- Public park and regulatory signs

Our deep knowledge of marine environments ensures every sign we create lives up to the promise of lasting brilliance. Explore our yacht sign portfolio to see our work in the world’s most demanding conditions.

Frequently Asked Questions about UV Resistant Signs

Here are honest answers to the most common questions we receive about UV resistant signs.

How long do UV resistant signs actually last?

The lifespan depends on materials, protective coatings, and the environment. Standard UV prints last 2-5 years, but our high-quality plastic signs have an estimated lifespan of 5+ years. In the marine world, our lighted LED yacht lettering made from marine-grade materials can last up to 8 years, backed by a 3-year warranty. Longevity is a direct result of material quality and a proper environmental assessment.

Are some colors more prone to fading than others?

Yes. Due to their molecular structure, certain pigments are more vulnerable to UV degradation. Reds and yellows tend to fade faster than blues and blacks. We combat this by using high-quality UV inks with robust inhibitors, ensuring all colors stay vibrant for much longer. This is a key detail that separates professional-grade signage from budget alternatives.

Can an existing sign be made more UV resistant?

Yes, but with limitations. Applying a protective laminate film or a UV-protective clear coat can extend a sign’s life by adding a new defensive layer. However, if the sign is already faded or cracked, this will only slow further deterioration, not restore its original look. We recommend a professional assessment to determine if retrofitting is cost-effective or if a replacement with a properly engineered UV resistant sign offers better long-term value.

Conclusion: Making an Enduring Choice for Your Brand

On a luxury yacht, every detail tells a story of quality and excellence. Your signage should tell that same story. Choosing UV resistant signs is a statement that you value the difference between good enough and genuinely exceptional.

We’ve covered the science of UV degradation, the superior materials like marine-grade stainless steel and high-performance acrylics, and the protective finishes that ensure longevity. Combining these elements with proper maintenance isn’t just buying a sign; it’s investing in your vessel’s reputation. The benefits are clear: reduced replacement costs, maintained visibility, and a professional appearance that reinforces the quality of your yacht.

At YachtSigns, we are boaters designing for boaters. For nearly two decades, we’ve combined traditional craftsmanship with modern technology to create premium, USA-manufactured UV resistant signs. Our global presence across the USA, Australia, Asia, Europe, and the Middle East allows us to understand and address the unique challenges of any marine environment.

Your yacht is a major investment. Don’t let substandard signage diminish its value or the impression it makes.