Why Professional Yacht Sign Installation Matters

Yacht sign installation is the final step in bringing your vessel’s identity to life, changing a carefully designed nameplate into a stunning focal point that reflects your personal style and craftsmanship standards.

Key aspects of yacht sign installation include:

- Professional vs. DIY options – Choose between expert installation or self-assembly kits

- Surface preparation – Proper cleaning, alignment, and protection of your yacht’s surfaces

- Precision drilling – Using CNC-cut templates for accurate hole placement and waterproof sealing

- Electrical integration – Connecting illuminated signs to your yacht’s 12V/24V power system

- Marine-grade materials – 316L stainless steel fixings and Tef-Gel to prevent corrosion

- Timeline – Single signs typically installed in one day, complex illuminated signs may take 1-3 days

As one yacht owner noted, “Yacht ownership is a passionate affair. Choosing her name confirms your creativity and selecting a design reflects your personal style.” The installation process requires the same attention to detail and precision that goes into every other aspect of your vessel.

Professional installation ensures water-tight seals, proper electrical connections, and adherence to marine industry standards. Most yacht owners prefer this approach for peace of mind, especially for illuminated signs that require precise drilling and wiring.

Whether your yacht is in the water or on dry land, experienced marine technicians can handle the complexities of working with curved surfaces, dissimilar metals, and harsh marine conditions. They bring specialized tools, templates, and knowledge of shipyard etiquette that protects both your investment and your vessel’s integrity.

I’m Cole Reilly, and with nearly two decades of experience in custom yacht sign manufacturing and installation, I’ve overseen more than 10,000 projects worldwide. This comprehensive guide draws from real-world yacht sign installation expertise to help you achieve flawless results that honor your vessel’s character and your passion for yachting.

The Journey from Concept to Creation: Design and Materials

Every great yacht sign installation begins with a spark of inspiration. Your vessel’s name represents more than just identification—it embodies your passion, your story, and your unique connection to the sea.

Our design process starts with collaboration, not assumption. We believe every yacht has its own character, and your signage should capture that perfectly. Through detailed virtual mockups, we transform your vision into reality before the first piece of metal is cut or the first hole is drilled.

Our graphic design team visits every vessel in person to take precise measurements and photographs. This hands-on approach ensures we understand your yacht’s unique curves, existing hardware, and aesthetic style. No two boats are identical, which is why we never work with generic templates or one-size-fits-all solutions.

The virtual mockup phase is where the magic happens. You’ll see exactly how your new signage will look on your specific vessel, allowing us to perfect the scale, placement, and style before fabrication begins. This collaborative process eliminates surprises and ensures you’re completely satisfied with the design concept.

More info about Boat Name Design

See our work

Choosing Your Sign: Materials and Finishes

The harsh marine environment demands materials that can withstand salt spray, UV radiation, and constant temperature changes while maintaining their stunning appearance year after year.

Marine-grade 316L stainless steel serves as our foundation material for most yacht signage. This isn’t ordinary stainless steel—it’s the industry standard specifically engineered for marine applications. Its superior corrosion resistance ensures your sign will shine brilliantly for decades, even in the most challenging conditions.

For a more contemporary look, high-grade acrylic offers incredible versatility. This UV-resistant material prevents fading and degradation from sun exposure while allowing for intricate designs and stunning lighting effects. It’s particularly popular for illuminated installations where light transmission creates dramatic visual impact.

Custom wood options bring timeless elegance to classic yacht designs. Whether you prefer the warmth of teak or the richness of mahogany, our craftsmen can create wooden signage that complements your vessel’s traditional aesthetic.

The finishing options are where your personality truly shines through. Mirror-polished finishes create brilliant reflections that catch every ray of sunlight. Satin finishes offer understated elegance with reduced glare. For those seeking something extraordinary, we offer specialty finishes including titanium gold, 14kt gold leaf, chrome, anodizing, and powder coating that can be color-matched to your yacht’s gel coat or paint.

3D Lettering for Boats

UV Resistant Signs

Illuminating Your Identity: Lighting Options

Nothing transforms a yacht’s presence like expertly designed illumination. When the sun sets and harbor lights begin to twinkle, your illuminated yacht name becomes a guide of style and sophistication.

LED technology has revolutionized marine lighting with its energy efficiency and remarkable longevity. Our LED yacht lettering systems typically come with a three-year warranty and can last up to eight years, making them both practical and beautiful investments.

The halo-lit effect creates one of the most stunning visual presentations available. Light projects around each letter onto the mounting surface, creating a dramatic glow that’s visible from impressive distances. This technique works particularly well on dark-colored hulls where the contrast is most striking.

Edge-lit letters offer a more subtle but equally sophisticated approach. Light emanates from the letter edges themselves, creating clean, modern lines that appeal to contemporary yacht designs. This method works beautifully with acrylic materials.

For ultimate versatility, RGB color-changing systems allow you to transform your yacht’s appearance at the touch of a button. Match your lighting to special occasions, holidays, or simply your mood. Many owners enjoy cycling through different colors during evening entertaining.

The choice between warm and cool white lighting significantly impacts your yacht’s character. Warm white creates an inviting, classic atmosphere reminiscent of traditional yacht elegance. Cool white delivers crisp, modern appeal that complements contemporary designs. Vibrant blue has emerged as one of our most popular single-color options, perfectly capturing the essence of the marine environment.

Fiber optic systems provide unique aesthetic possibilities with their distinctive light distribution patterns. While less common than LED, they offer creative opportunities for truly custom installations.

Every lighting system we design is engineered specifically for the marine environment, ensuring your investment continues to shine brilliantly through countless voyages.

Illuminated Boat Names

How to Get Custom LED Signs for Yachts

More on Lighting

The Critical Choice: Professional vs. DIY Installation

The decision between professional yacht sign installation and going the DIY route might be the most important choice in your entire signage project. While we offer DIY options for those who love getting their hands dirty, there’s something to be said for watching experts work their magic on your vessel.

Think of it this way: you wouldn’t attempt to rewire your yacht’s navigation system after watching a YouTube video, right? Yacht sign installation involves many of the same complexities – curved surfaces that challenge even experienced installers, electrical systems that demand marine-grade expertise, and the unforgiving nature of saltwater environments.

We’ve designed our services to meet you wherever you are in your comfort zone. Some yacht owners thrive on the satisfaction of completing projects themselves, while others prefer sipping coffee on the flybridge while professionals handle the technical details.

The Professional Approach: Ensuring Flawless Execution

When you choose professional yacht sign installation, you’re investing in more than just labor – you’re buying peace of mind. Our close-knit team of six marine installation technicians has collectively installed thousands of signs on vessels ranging from sleek 10-meter sport yachts to magnificent 110-meter superyachts.

What sets our experienced marine technicians apart isn’t just their skill with tools – it’s their understanding of yacht culture. They know that arriving at a pristine marina requires shipyard etiquette that respects both your vessel and your neighbors. They understand that every yacht has its own personality, and they adapt their approach accordingly.

Our technicians travel worldwide with their specialized tools and access equipment, ready to tackle installations whether your yacht is nestled in a Mediterranean marina or hauled out in a Caribbean boatyard. When bucket lifts aren’t available, they’re equally comfortable working from harnesses and lifts, maintaining the same precision and safety standards.

The real magic happens in the details. Precision drilling and sealing becomes critical when you’re working with illuminated signs that require electrical connections. One small mistake with waterproofing can lead to expensive repairs months later. Our team treats every hole as if it were going into their own vessel.

Perhaps most importantly, our work comes with an installation warranty that backs up our confidence in the results. When you’re investing in signage that represents your yacht’s identity, that guarantee matters.

The DIY Route: What You Need to Know

For the hands-on yacht owner, we’ve engineered our products with self-installation in mind. There’s genuine satisfaction in completing a project yourself, especially when guests admire your yacht’s stunning new signage and you can say, “Actually, I installed that myself.”

Our DIY installation kits come with everything you need for success. The CNC-cut drilling templates take the guesswork out of positioning – they’re like having a professional’s precision without the professional’s schedule. These templates ensure your letters align perfectly, even on challenging curved surfaces.

The detailed instructions we provide aren’t just technical manuals – they’re written by people who understand that not everyone speaks “marine installation” fluently. We include the kind of tips and tricks that only come from years of real-world experience.

You’re never alone during a DIY installation. Our phone and email support connects you directly with our technical team, who can walk you through any challenges you encounter. They’ve probably seen your exact situation before and know exactly how to help.

DIY installation works beautifully for non-illuminated signs and smaller vessels where access is straightforward. However, we’ll be honest with you – illuminated signs requiring electrical connections and waterproofing demand a higher skill level. If you’re changing your yacht’s name, proper surface preparation is crucial: removing old lettering, filling and fairing, and ensuring a perfect foundation will make your new signage shine.

The choice between professional and DIY installation often comes down to your comfort level with marine electrical work and your available time. Either way, we’re here to ensure your yacht’s new identity is installed with the precision and care it deserves.

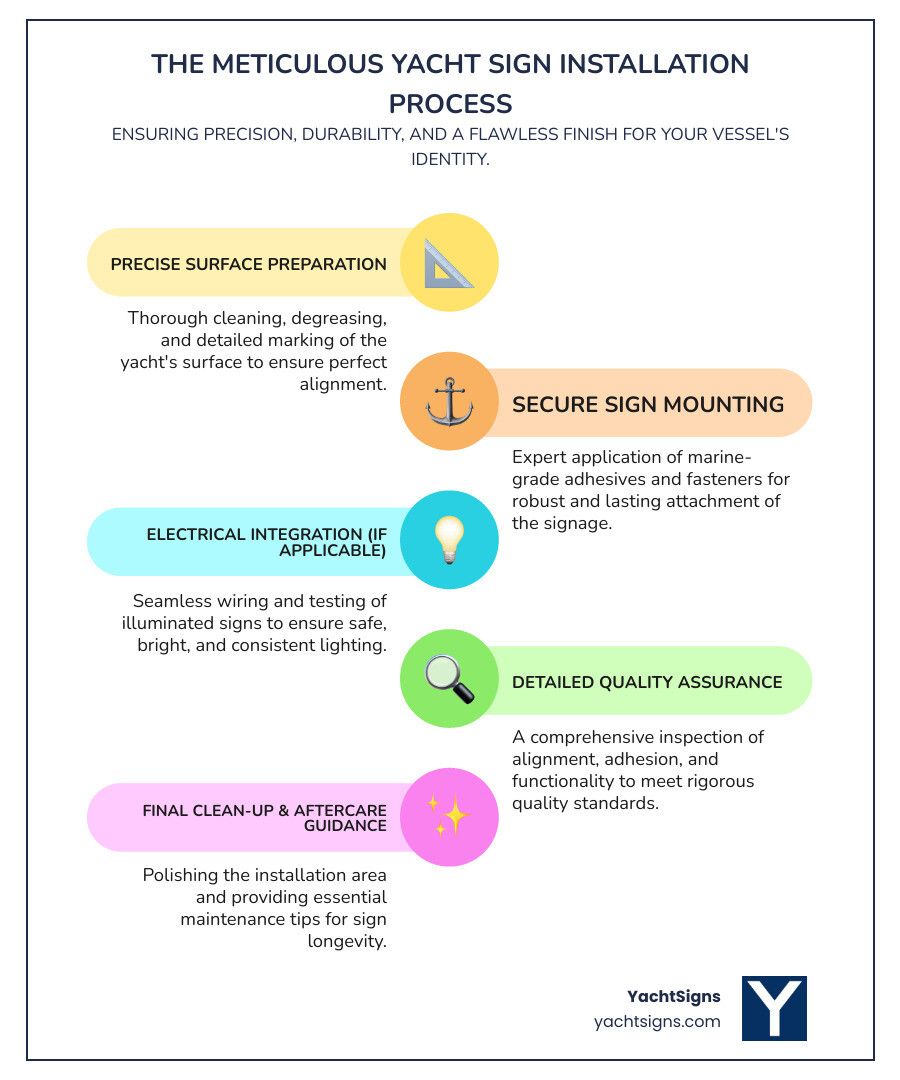

The On-Board Process: A Meticulous Yacht Sign Installation

This is where craftsmanship meets execution. A professional yacht sign installation is a carefully orchestrated process designed to protect your vessel while achieving a perfect fit and finish, whether the yacht is in the water or on the hard. Every step is planned with precision, ensuring your yacht receives the respect it deserves while we transform your vision into reality.

Preparing Your Vessel for the New Signage

Before our technicians arrive with their tools and expertise, proper preparation sets the stage for a flawless yacht sign installation. Think of it as preparing a canvas for a masterpiece—every detail matters.

Removing old lettering is often the first step if you’re renaming your yacht. This isn’t simply peeling off vinyl; any existing 3D names need professional removal to avoid damage. The underlying area will then need to be filled, faired, and repainted to create a smooth, uniform surface that’s worthy of your new signage.

Surface preparation follows next, and we can’t overstate its importance. The mounting area must be absolutely clean, dry, and free of any debris or residue. Even the smallest bit of wax or salt residue can compromise the installation, so we take this step seriously.

Securing access to the vessel requires coordination with your marina or shipyard. We’ll need permission to work on-site, and for larger signs or challenging locations, arranging for scaffolding or lifts in advance is essential. Don’t worry if these aren’t available—our experienced technicians can work via harness when necessary, though it’s always safer and more efficient with proper access equipment.

For illuminated signs, ensuring power availability is crucial. We’ll need a mains electricity supply for testing your new sign and powering our precision tools. Our team will coordinate these requirements with you well before installation day.

We treat every yacht as if it were our own, working tidily and respectfully throughout the entire process. Your vessel’s pristine condition is our priority.

The Technical Yacht Sign Installation Method

The actual yacht sign installation is where technical precision meets artistic vision. Our technicians have refined this process over thousands of installations, and it shows in every perfectly aligned letter.

Template alignment begins with our precisely CNC-cut drilling templates, which map out exact letter spacing and hole positions. Here’s where experience matters most—we typically measure parallel from a known level edge, such as your swim platform or transom centerline. You might think we’d use a spirit level, but experienced installers know better. Yachts often sit with a slight list, so relying on visual alignment from the dock usually gives the most pleasing result.

Protecting paint and teak surfaces is non-negotiable during the drilling process. We carefully cover surrounding areas with protective materials like blue foam, preventing any scratches or damage from drilling debris. Your yacht’s finish took considerable time and expense to perfect, and we’re committed to preserving it.

Precision drilling follows the template exactly, creating the minimal holes necessary for mounting bolts and wiring. Every hole serves a purpose, and we never drill more than absolutely required.

Mounting with spacers for hull curvature addresses one of the most challenging aspects of yacht signage. Our letters are designed to mount flat and should never be forced to conform to curved surfaces. Instead, we provide custom spacers—whether rubber, acrylic, or stainless steel—that allow letters to sit perfectly flat while accommodating your yacht’s unique shape. Our mounting systems are engineered around existing features like door openings, storage compartments, and portholes.

Applying marine-grade sealant creates the watertight barrier that protects your vessel’s integrity. Every drilled hole and fastener receives marine-grade sealant, ensuring no water can ever find its way into your hull.

Through-hull stud mounting provides the robust attachment your signage deserves. When fastening internally, our technicians know that proper technique matters more than brute force. An “over pinch tighten” with two full nuts counter-locked creates a secure seal while preventing vibration loosening. We specifically avoid Nylock nuts in marine applications—experience has taught us what works best in saltwater environments.

Powering the Brilliance: Electrical and Technical Considerations for your Yacht Sign Installation

For illuminated signs, electrical integration transforms your yacht sign installation from impressive to absolutely stunning. This phase requires careful planning and flawless execution to ensure both safety and long-term reliability.

12V/24V DC power systems are the standard in yachting, and our illuminated signs integrate seamlessly with your existing electrical setup. Whether your yacht runs on 12V or 24V, our LED systems are designed to work efficiently with your power configuration.

Connecting to the yacht’s electrical panel requires qualified technicians who understand marine electrical systems. Our team carefully routes wiring and makes proper connections, ensuring correct voltage and current supply while maintaining your yacht’s electrical integrity.

Waterproof connections are absolutely critical in the marine environment. Every electrical connection uses marine-grade, waterproof components specifically designed to resist saltwater corrosion and prevent short circuits. We’ve seen too many beautiful installations ruined by substandard electrical work, so we never compromise on these components.

Cable management might seem like a small detail, but it makes a huge difference in long-term reliability. LED wiring and fiber optic cables are secured with high-quality cable ties to prevent tugging or kinking. Good access behind each letter is essential for managing wiring and tightening fixings, which is why we plan cable routes carefully during the design phase.

Preventing dissimilar metal contact addresses one of the marine environment’s biggest challenges: galvanic corrosion, also known as electrolysis. This occurs when different metals come into contact in the presence of saltwater, creating a battery effect that can seriously damage your yacht. We use 316L marine-grade stainless steel for all fixings specifically to minimize this risk.

Using Tef-Gel or isolation sleeves provides an extra layer of protection against electrolysis. We coat any threads and fixings that contact dissimilar metals with Tef-Gel, a specialized marine compound. When necessary, we also provide fixing sleeves that physically isolate different metals, protecting both your yacht’s hull and your sign’s long-term integrity.

Aftercare and Assurance: Maintenance, Warranty, and Repairs

The relationship with your yacht sign doesn’t end after yacht sign installation. Proper care, backed by a solid warranty, ensures your vessel’s name remains as brilliant as the day it was fitted. We believe in providing long-term support for our products.

Protecting Your Investment: Warranty and Guarantees

We stand behind the quality of our products and our yacht sign installation services:

- Installation Guarantee: Our professional installation work is guaranteed, providing you with confidence and peace of mind.

- Manufacturer Warranty: Our lighting solutions typically come with a three-year warranty, and the LED lighting itself can last for years, often up to 8 years, depending on usage (24/7 vs. occasional).

- Coverage Details: Before leaving, the sign is thoroughly tested, and clients receive necessary documentation, diagrams, and contact details for ongoing support. We also offer a lifetime warranty on our lighted sign products, demonstrating our commitment to enduring quality.

Long-Term Care for Lasting Luster

To maintain the pristine appearance and longevity of your yacht sign, especially those made of polished stainless steel, regular care is essential:

- Regular Rinsing with Fresh Water: The most important step is to regularly rinse your sign with fresh warm water to remove salt residue, which can cause corrosion and dullness.

- Cleaning with Mild Detergent: For stubborn stains on stainless steel, use hot water with a mild detergent and a soft cloth.

- Using Microfiber Cloths: Always use soft microfiber cloths for cleaning and detailing to avoid scratching the surface.

- Polishing Stainless Steel Yacht Signs: After cleaning, you can polish stainless steel signs to restore their luster.

- Avoiding Abrasive Cleaners: Never use abrasive cleaners, scourers, or harsh chemicals like Jif-type cream cleaners on your yacht sign, as these can damage the finish and accelerate corrosion.

Consistent maintenance ensures your sign remains a shining testament to your yacht’s identity.

Refits and Repairs: Reviving Your Yacht’s Identity

Yachts evolve, and sometimes, so does their identity. We offer comprehensive services for refits and repairs, ensuring your signage always looks its best:

- Professional Removal of Old Signs: We can professionally remove old vinyl or 3D yacht names, preparing the surface for new signage.

- Repairing Scratches or Damage: Accidents happen. We can repair signs that are scratched, damaged, or showing signs of wear.

- Refitting with New Signage: Whether you’re upgrading your yacht’s look, changing its name, or simply refreshing existing signage, we handle the entire refitting process.

- Upgrading to Illuminated Letters: For those looking to improve their yacht’s presence, we can upgrade non-illuminated signs to stunning illuminated letters.

- LED Layer Failure Repair: Should the lighting components experience issues, we provide repair services for LED layer failure, restoring your sign’s brilliance.

We can approach your project through retrofitting, renaming, or starting from scratch, always ensuring a seamless and high-quality outcome.

Frequently Asked Questions about Yacht Sign Installation

How long does the installation process take?

The timeline for yacht sign installation depends entirely on what you’re having installed. If you’re adding a simple, non-illuminated sign to your vessel, our technicians can typically complete the work in just one day. It’s straightforward and efficient.

However, illuminated signs are a different story altogether. These beautiful, glowing installations require much more precision and care. An illuminated nameboard typically takes one to three full days to complete properly. This isn’t us taking our time – it’s about doing the job right.

During those days, we’re carefully drilling precise holes, running and connecting all the wiring to your yacht’s electrical system, applying marine-grade sealants, and thoroughly testing everything multiple times. We want to make absolutely sure your new sign will shine brilliantly for years to come.

For larger projects involving multiple signs or additional elements like hailing ports, we’ll discuss the timeline with you upfront so you know exactly what to expect.

Will you need to drill holes into my yacht?

Yes, and we understand this can feel a bit nerve-wracking! For illuminated signs and most stud-mounted lettering, carefully drilled holes are absolutely necessary. These holes serve two critical purposes: they allow the mounting bolts to pass through for a secure attachment, and they provide pathways for the wiring that powers your illuminated signs.

Here’s what makes this process safe and precise: we use CNC-cut templates that map out every single hole in advance. This means there are no surprises, no guesswork, and no unnecessary holes. We keep drilling to the absolute minimum required for a rock-solid installation.

Our professional installers treat your yacht like their own. Every hole is carefully sealed with marine-grade sealant to create a perfectly waterproof fit. This protects your hull’s integrity and prevents any water from getting where it shouldn’t be. It’s a normal and necessary part of creating robust, long-lasting signage that can handle everything the marine environment throws at it.

Can signs be installed while the yacht is in the water?

Absolutely! Yacht sign installation can definitely be performed while your yacht is floating. Our experienced technicians are well-equipped to work in marinas, at floating docks, in refit yards, or even during a yacht’s launch. We’ve done installations in all sorts of locations around the world.

That said, for complex illuminated signs that require scaffolding or cherry pickers, working on dry land often makes the process safer and more efficient. When we’re working over water, we need specialized safety equipment and have to account for different risks like tides, boat movement, and limited access.

We’re fully prepared for either scenario and will work with you to determine the best approach for your specific situation. Whether your yacht is hauled out or floating peacefully at the dock, we’ll make sure your new signage gets installed with the same level of precision and care.

Conclusion

A beautifully crafted and expertly installed yacht sign is the ultimate expression of a vessel’s character. The process, from design through yacht sign installation, is a blend of artistry and technical precision. By understanding the key steps—choosing quality marine-grade materials, deciding on professional installation, and committing to proper maintenance—you ensure your yacht’s name is a lasting guide of brilliance. We are dedicated to providing this level of excellence, delivering flawless results that honor the passion of yacht ownership.