Lift Your Vessel’s Identity with a 3D Print Boat Name

Starting on the journey to personalize your vessel, you might wonder about the best way to display its name. A 3d print boat name offers a modern, sophisticated solution, combining cutting-edge technology with unparalleled customization. It’s quickly becoming the preferred method for discerning yacht owners.

Why choose a 3D printed boat name? Here’s a quick look at the advantages:

- Unrivaled Customization: Create any font, size, or style. Add unique logos or effects.

- Superior Durability: Made with marine-grade materials that resist UV, water, and salt.

- Modern Aesthetics: Achieve a premium, high-end look that stands out.

- Precision and Quality: Enjoy perfectly crafted letters with intricate details.

- Efficient Process: Often faster than traditional custom sign creation.

Gone are the days when boat names were limited to simple vinyl or standard metal letters. 3D printing opens up a world of design possibilities. Imagine your boat’s name in a truly unique font, with custom depth and finish, perfectly reflecting your style and the elegance of your yacht.

As Cole Reilly from Yacht Lettering, I’ve spent nearly two decades perfecting marine signage. With over 10,000 projects completed, I bring expert knowledge in yacht lettering graphics, including the innovative field of 3d print boat name solutions, ensuring your vessel makes a statement.

Important 3d print boat name terms:

Why Choose a 3D Printed Name for Your Boat?

Picture this: you’re walking down the marina, and one boat catches your eye immediately. Its name isn’t just painted on or stuck with vinyl – it has depth, character, and a premium look that screams quality. That’s the magic of a 3d print boat name.

When we started exploring 3D printing for marine signage, we quickly realized we were looking at a game-changer. Traditional methods like vinyl decals and metal letters have served us well over the years, but they come with real limitations that 3D printing simply eliminates.

Best design freedom is where 3D printing truly shines. With vinyl, you’re stuck with flat lettering – no depth, no texture, just a basic decal look. Metal letters offer more presence, but creating custom fonts or intricate designs can be incredibly expensive and time-consuming.

With a 3d print boat name, your imagination becomes the blueprint. We can create letters with varying thicknesses, add custom textures that catch the light beautifully, and incorporate your boat’s logo directly into the design. Want your name to have a wave pattern running through it? No problem. Prefer letters that gradually increase in depth? We can make that happen.

The cost-effectiveness often surprises our clients. While professional 3D printing equipment represents a significant investment for us, the actual material costs for creating your boat name are typically much lower than custom metal fabrication or hand-carved wood. This efficiency allows us to offer premium, highly customized signage at prices that make sense for boat owners who want something special without breaking the bank.

Material innovation in 3D printing has been remarkable. We’re not talking about basic plastic here – these are advanced marine-grade polymers engineered specifically for harsh outdoor conditions. Materials like ASA, PETG, and carbon fiber reinforced composites are designed to handle everything Mother Nature throws at them: constant UV exposure, saltwater spray, temperature swings, and even the occasional dock bump.

This brings us to superior durability compared to traditional options. A quality vinyl decal might give you three to five good years before it starts cracking, fading, or peeling – especially in direct sunlight and saltwater environments. Metal letters can develop corrosion or pitting over time, and their finish may dull despite your best maintenance efforts.

A properly finished 3d print boat name made from marine-grade materials maintains its crisp appearance for many years with minimal care. The combination of advanced materials and professional finishing techniques creates signage that looks as good in year ten as it did on installation day.

The fast turnaround aspect keeps getting better as our processes improve. Once you approve the design, the 3D printing process runs largely automated. This means we can move from your final approval to finished product much faster than traditional methods that might involve casting, machining, or extensive hand-finishing work. Speed without compromise – that’s what modern fabrication technology brings to the table.

| Feature | 3D Printed Boat Name | Traditional Vinyl Lettering | Traditional Metal Lettering |

|---|---|---|---|

| Design Freedom | Unlimited; complex shapes, varying depths, custom textures, integrated logos | Limited to flat, 2D shapes and basic fonts | Good for classic fonts; complex designs expensive; limited depth options |

| Cost-Effectiveness | Highly competitive for custom designs; efficient material usage | Low initial cost for basic designs; expensive for large or complex work | High initial cost, especially for custom designs |

| Material Innovation | Advanced marine-grade polymers (ASA, PETG, carbon fiber composites) | PVC vinyl; prone to fading and cracking | Brass, stainless steel, aluminum; requires maintenance to prevent corrosion |

| Durability | Excellent UV, saltwater, and impact resistance; long lifespan | Good short-term; degrades in harsh marine environments | Very durable with proper maintenance; can tarnish or corrode |

| Turnaround Time | Fast once design is finalized | Very fast for simple designs; slower for complex work | Can be lengthy due to machining and finishing processes |

Designing Your Custom 3D Boat Name

Creating your 3d print boat name is truly where the magic happens! This is the exciting stage where your unique vision starts to take shape, moving from an idea to a detailed digital model. We love this part because it’s a perfect blend of artistic creativity and careful technical work.

Our journey often begins with specialized CAD software (Computer-Aided Design). Think of these powerful tools as our digital sculpting studio. They let us craft your letters in three dimensions, carefully defining their height, depth, and overall shape. We can take your chosen font or logo, often starting as vector graphics, and then “extrude” them. This is how we give them that wonderful 3D effect you’re looking for. It’s like shaping virtual clay, but with incredible precision.

Choosing the right font selection is a big deal. The typeface you pick can say a lot about your boat’s personality – whether it’s neat, powerful, or a bit playful. We have a huge collection of fonts to explore, and if you have a special one in mind, we can usually make it work. Beyond the font itself, we also consider letter thickness. A thicker letter can feel more solid and make a bolder statement, while a shallower depth might be more subtle. These choices affect both how your name looks and how strong it will be.

And let’s not forget about logos and graphics! Many boat owners want to add a unique emblem, perhaps a family crest, or a cool graphic alongside their boat’s name. 3D printing is fantastic for this. It can create even the most intricate details with amazing accuracy, making them a smooth part of the overall design. Whether it’s a stylish wave, a classic compass rose, or your own custom symbol, we can bring it to life in three dimensions, making sure it perfectly matches your boat name.

Want to dive deeper into how we make stunning 3D lettering? Check out our detailed insights on More info about 3D Lettering for Boats.

Adhering to Boat Name Regulations

While we can get super creative with your 3d print boat name, it’s also really important to remember that there are rules for boat names and identification. These rules are put in place for good reasons: they help with safety, make it easier to identify boats in an emergency, and help with official paperwork. We always make sure our clients are aware of these guidelines right from the start.

One of the most important things is legibility requirements. Your boat name must be easy to read, even from a distance. This means picking a font that isn’t too fancy or hard to make out. The size of the letters also matters. While most recreational boats don’t have super strict minimum size rules, larger vessels often do. We always suggest choosing letters that look right for your boat’s size and can be seen clearly.

Size and placement rules can change depending on how your boat is registered and where you plan to use it. For example, boats registered with the U.S. Coast Guard (called “documented vessels”) have very specific rules for where the name, hailing port, and Official Number go. Recreational boats usually have more freedom. But it’s just good sense to put your boat name clearly on the back (transom) and often on both sides of the front (bow).

Your hailing port information – which is the city and state where your boat is usually kept or registered – also needs to be shown. It usually goes right under your boat name on the back. Just like your boat name, it needs to be easy to read.

For documented vessels, the Official Number (ON) display is a must. This special identification number needs to be permanently fixed inside your boat, usually in a spot that’s easy to see, like on a main support beam. While this isn’t part of your exterior 3d print boat name, it’s a key regulation for identifying your vessel.

It’s always a smart move to check official sources for the most current rules that apply to your specific boat and where you’ll be sailing. Organizations like BoatUS offer great summaries of these regulations. For more detailed info on boat lettering rules, you can look at resources like Boat Lettering – BoatUS . Making sure we follow these rules from the design stage helps everyone avoid problems later on.

The Technical Guide to a Marine-Ready 3D Print Boat Name

Creating a 3d print boat name that truly lasts in the unforgiving marine environment requires more than just a cool design; it demands the right materials, precise printing, and meticulous finishing. This is where our expertise in both traditional craftsmanship and modern fabrication technology truly shines.

Choosing the Best Materials for a Marine Environment

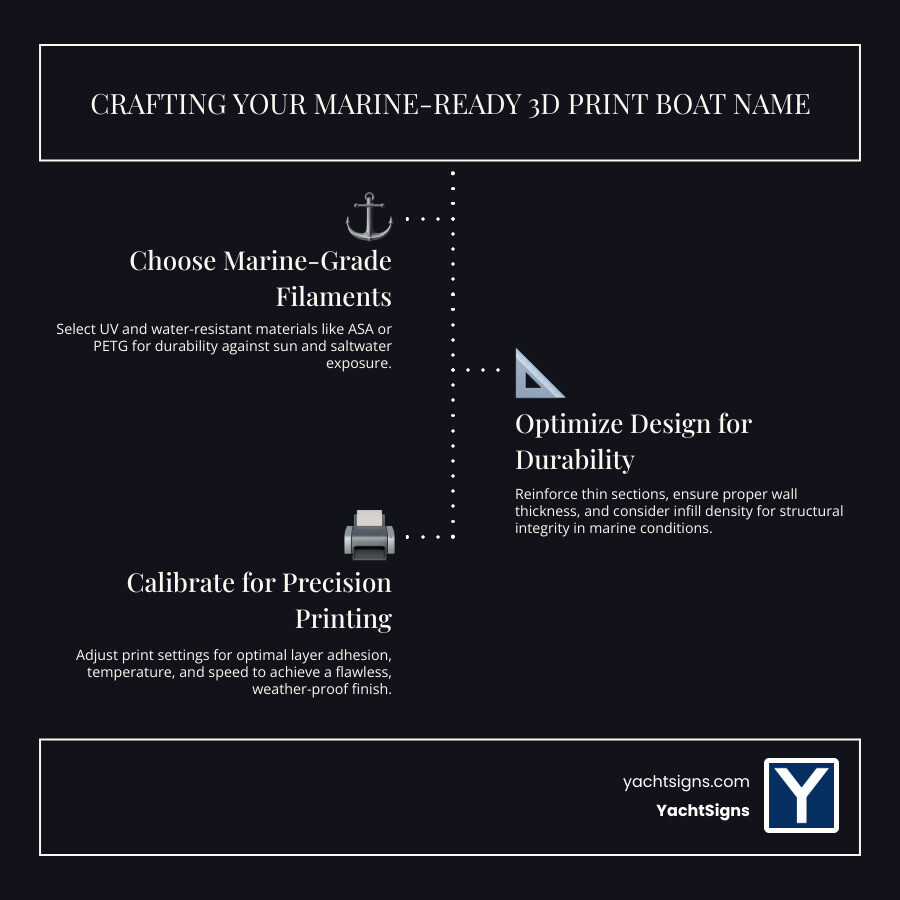

The ocean is a harsh mistress, and any material exposed to it needs to be incredibly resilient. When selecting materials for a 3d print boat name, we prioritize several key properties:

- UV resistance: The sun’s ultraviolet rays are a major culprit for degrading plastics, causing them to become brittle, discolored, and weak. Materials with inherent UV stability are essential to prevent fading and structural degradation.

- Saltwater corrosion: While plastics don’t “corrode” in the same way metals do, saltwater can still affect their surface, encourage biological growth, and accelerate degradation if the material isn’t suitable.

- Impact strength: Boats are dynamic environments. A boat name needs to withstand bumps, vibrations, and occasional knocks without cracking or breaking.

Based on these critical factors, we rely on premium marine-grade materials such as ASA, PETG, and Carbon Fiber reinforced composites.

- ASA (Acrylonitrile Styrene Acrylate): Often considered the “outdoor ABS,” ASA is highly regarded for its excellent UV resistance, weatherability, and good mechanical properties. It holds up exceptionally well against prolonged sun exposure and harsh outdoor conditions, making it a top choice for a 3d print boat name. It resists color fading and maintains its structural integrity over time.

- PETG (Polyethylene Terephthalate Glycol): PETG is known for its durability, chemical resistance, and ease of printing. It offers good impact strength and transparency (if desired), and while not as UV resistant as ASA, it performs significantly better than standard PLA or ABS in outdoor settings. It’s a versatile choice, especially when combined with protective coatings.

- Carbon Fiber reinforced composites: For ultimate strength and rigidity, especially in larger or more intricate designs, we may use composite filaments infused with carbon fiber. These materials offer exceptional stiffness, dimensional stability, and reduced weight, making them ideal for high-performance applications where resistance to flexing and impact is paramount. They also often have improved temperature resistance.

Each of these materials, when properly processed and finished, contributes to the longevity and aesthetic appeal of your 3d print boat name. We understand that a sign is only as good as the material it’s made from. For more information on protecting your signage, explore our insights on More info about UV Resistant Signs.

Recommended 3D Printing Best Practices

Beyond material selection, the actual 3D printing process itself is critical to the quality and durability of your 3d print boat name. We employ professional-grade 3D printing equipment that offers precise control over every aspect of the print. Consumer-grade printers can be fine for prototypes, but for a finished product destined for the marine environment, industrial-grade machines provide the consistency and reliability needed.

Key print settings are carefully optimized:

- Optimal layer height and infill: A finer layer height (e.g., 0.15mm-0.2mm) results in smoother surfaces, requiring less post-processing, and provides better detail. High infill percentages (e.g., 50-100%) create a denser, stronger part, crucial for resisting impacts and environmental stresses. We aim for solid or near-solid infill for maximum durability.

- Print orientation for strength: This is a subtle but vital factor. Printing a letter flat on the build plate might seem intuitive, but depending on the geometry, printing it on its side or at an angle can significantly improve its strength along critical stress points. We analyze the design to determine the optimal orientation that maximizes layer adhesion and minimizes weak points.

- Support structures: For complex geometries or overhangs, support structures are necessary to prevent sagging during printing. We use dissolvable or breakaway supports that can be carefully removed without damaging the finished surface.

- Quality assurance: Every print undergoes rigorous inspection. We check for layer adhesion, dimensional accuracy, surface finish, and any imperfections. This meticulous attention to detail ensures that only flawless components proceed to the finishing stage.

Post-Processing: How to Finish Your 3D Print Boat Name

A raw 3d print boat name emerging from the printer is just the first step. To achieve that premium, marine-ready finish that YachtSigns is known for, extensive post-processing is essential. This is where modern technology meets traditional craftsmanship.

First, sanding techniques are employed to smooth out any layer lines or imperfections left by the printing process. This is a multi-stage process, starting with coarser grits to remove major blemishes and progressing to finer grits (e.g., 220, 400, 600 grit) for a silky-smooth surface. For intricate details, precision tools and careful hand-sanding are necessary.

Once sanded, the part is thoroughly cleaned before priming. A high-quality marine-grade primer is applied. This step is crucial as it creates an ideal surface for paint adhesion, fills any remaining micro-imperfections, and provides an additional barrier against moisture. We use primers formulated for plastics and harsh outdoor conditions.

Next comes the magic of marine-grade paints. These are not your average spray paints. Marine paints are specifically engineered to withstand UV radiation, saltwater, abrasion, and chemicals. They offer excellent color retention and gloss, ensuring your 3d print boat name looks vibrant for years. We apply multiple thin coats for a durable, even finish, allowing proper drying time between each coat. Custom color matching is also possible to perfectly complement your boat’s hull or existing accents.

Finally, for ultimate protection and a deep, lustrous shine, a UV-resistant clear coat is applied. This clear coat acts as a sacrificial layer, protecting the underlying paint from UV degradation, scratches, and environmental fallout. For even greater durability and a glass-like finish, epoxy sealing can be applied. A marine-grade epoxy creates an incredibly tough, waterproof, and UV-stable barrier, encapsulating the entire 3d print boat name and providing unparalleled protection against the elements. This multi-layered approach to finishing ensures that your boat name not only looks stunning but also endures the rigors of the marine environment for a very long time.

Installation and Maintenance for Lasting Appeal

Your beautifully crafted 3d print boat name deserves a flawless installation that will showcase it for years to come. Think of this final step as the difference between a good job and a truly professional result – it’s where our craftsmanship expertise really shines through.

The foundation of any lasting installation begins with meticulous surface preparation. Your boat’s hull might look clean, but appearances can be deceiving. Any traces of wax, polish, salt residue, or old adhesive will compromise the bond between your 3d print boat name and the hull. We recommend starting with a thorough hull cleaning using marine-grade degreasers followed by a final wipe-down with isopropyl alcohol. This extra step might seem tedious, but it’s the difference between a sign that lasts a season and one that stays put for decades.

Here’s where patience pays off: creating a mounting template. This simple step prevents the heartbreak of crooked letters or uneven spacing. We typically create a paper or vinyl template that matches your 3d print boat name layout exactly. Tape it temporarily to your hull, step back, and make sure everything looks perfect. Mark your mounting points through the template, then remove it. This method eliminates guesswork and ensures that professional, symmetrical appearance that makes people stop and admire your vessel.

For comprehensive guidance on boat signage solutions, explore our More info about Boat Signs.

Securely Mounting Your 3D Print Boat Name

When it comes to actually attaching your 3d print boat name, we have several proven methods that we often combine for maximum security and longevity. The choice depends on your letter size, hull material, and local conditions.

Marine-grade epoxy creates an incredibly strong, permanent bond that laughs at saltwater and temperature swings. This two-part adhesive forms a waterproof connection that’s often stronger than the materials it’s joining. For larger or heavier letters, epoxy provides the rock-solid foundation you need. The key is working quickly once mixed – you’ll have a limited window to position everything perfectly.

3M VHB tape might sound too simple to work, but this industrial-strength foam tape has secured everything from skyscraper panels to race car parts. Its foam core acts like a shock absorber, accommodating the natural flex of your hull while maintaining an incredibly strong bond. It’s particularly effective for lighter letters or as a supplement to other mounting methods.

For the ultimate in strength and clean appearance, stud mounting embeds threaded posts directly into your letters during production. Corresponding holes in your hull allow the letters to mount flush with no visible hardware. This traditional approach offers exceptional resistance to the shear forces that can challenge other mounting methods.

Some installations benefit from mechanical fasteners – small, discrete stainless steel screws that provide additional security. While not always necessary, they can offer peace of mind for larger installations or boats that see heavy weather.

Our preferred approach often combines these methods. For example, stud mounting for structural integrity with marine-grade adhesive for a complete seal. This belt-and-suspenders approach ensures your 3d print boat name stays exactly where it belongs, whether you’re cruising calm waters or powering through chop.

Long-Term Care and Durability

A professionally crafted 3d print boat name from YachtSigns is built to last, often outliving the boats they’re mounted on. With proper materials and finishing, you can expect a lifespan that rivals or exceeds traditional alternatives while looking better throughout its life.

Regular cleaning is really all the maintenance your sign needs. Just like washing your boat, a gentle rinse with fresh water and mild boat soap keeps everything looking pristine. Use a soft cloth or sponge – nothing abrasive that might scratch the protective clear coat. The best habit you can develop is rinsing off saltwater after each outing. Salt is persistent stuff, and while your 3d print boat name is designed to handle it, why not make its job easier?

Periodic inspection for damage takes just a minute but can save major headaches later. Look for any chips, cracks, or areas where the clear coat might be compromised. Catching small issues early means simple repairs instead of major restoration work.

Should you notice minor damage, touch-up procedures can often restore the original appearance. Small paint chips can be carefully touched up with matching marine-grade paint. If the clear coat gets scratched, a light sanding and fresh clear coat application can make it look like new again. For anything more significant, professional repair ensures your 3d print boat name maintains its showroom appearance.

The beauty of this approach is simplicity. With minimal care, your custom boat name will continue turning heads and proudly displaying your vessel’s identity for many years of trips on the water. For additional insights on maintaining your marine signage, check out our information on More info about Boating Signs.

Conclusion

The marine industry is witnessing a revolution, and 3d print boat name technology is leading the charge. What we’ve explored together represents more than just a new way to display your vessel’s identity – it’s the future of boat signage.

Think about it: we’ve moved from simple vinyl decals that peel and fade to sophisticated, three-dimensional art pieces that can withstand whatever Mother Nature throws at them. This isn’t just technological progress; it’s a leap forward in how we think about personal expression through innovative design.

Your boat’s name tells a story. Maybe it honors a loved one, captures a dream, or reflects your adventurous spirit. A 3d print boat name gives that story the voice it deserves – bold, distinctive, and built to last. The design freedom we’ve discussed means your vessel can truly stand out in any marina, from the Mediterranean to the Caribbean.

At YachtSigns, we understand that professional craftsmanship isn’t just about having the right equipment or materials (though our marine-grade ASA and carbon fiber composites certainly help). It’s about caring for each project as if it were our own vessel. With nearly two decades in the marine signage industry and over 10,000 completed projects, we’ve learned that the difference between good and exceptional lies in the details.

Our approach combines the time-honored traditions of marine craftsmanship with cutting-edge 3D printing technology. We’re not just keeping up with innovation – we’re helping to define it. Whether your yacht calls home to a marina in the USA, Australia, Europe, or anywhere across the seven seas, we bring the same commitment to quality and attention to detail that has made us a trusted name in YachtSigns expertise.

The beauty of this technology is that it democratizes premium design. Features that once required expensive custom machining or hand-carving are now achievable through intelligent design and precise fabrication. Your 3d print boat name can have the same sophisticated appearance as signage costing thousands more, without compromising on durability or visual impact.

Ready to give your vessel the identity it deserves? We’re here to guide you through every step – from initial concept to final installation. Let’s create something remarkable together. Explore Custom Yacht Signage Solutions and find how a 3d print boat name can transform your boat from simply functional to absolutely unforgettable.